The currently prevalent economic model is that of a linear economy. This type of economy is most commonly described as following a take, make and dispose model. Value is created by producing and selling as many products as possible.

The circular economy model follows a very different procedure. Where feasible, closed loop material cycles are employed. That way, a great deal of the value of the material flows is preserved: the life cycle is extended as far as possible; re-use is optimised and the materials can be recycled after use. There are two main cycles in the circular economy model they are the Organic Cycle and the Technical Cycle.

THE ORGANIC CYCLE

The circular economy model is inspired primarily by natural ecosystems: toxic substances are neutralised and waste products are non-existent, as all residues are transformed into nutrients for the ecosystem. This applies to all materials that are rapidly biodegradable in principle, and therefore could apply to any intelligently designed and manufactured consumables. The general principle here is complete transformation into nutrients of the substances in question after use, so they cease to exist in their current state. Therefore, this is known as the Organic Cycle

THE TECHNICAL CYCLE

Other materials are not biodegradable, or are only over the long term, and their concentrated presence can have a disruptive or even harmful effect on ecosystems – think of car tyres, for example. This group includes most man-made consumables: furniture, cars, tools, textiles, etc. Here, the general principle is possible reuse as raw materials for similar products and/ or possible recycling for use in other products. The material structure is not destroyed, but the shape or appearance may be completely transformed. This is known as the technical cycle.

It is not that one of these two cycles is good and the other is bad, but that each cycle applies to completely different material flows, requiring a specific approach. The two cycles are not just capable of co-existing in harmony, together they ensure that all material flows are optimally processed, that they are not mixed together and that what we now consider ‘waste’ is eliminated to the fullest possible extent.

In 2002 German chemist Michael Braungart and American architect Bill McDonough described the foundation of such an approach in their book Cradle to Cradle: Remaking the Way We Make Things. Prior to this publication, the ecological principle was usually described as ‘Cradle to Grave’ to emphasise consideration of the entire product life cycle. With this publication Braungart and McDonough changed that to ‘Cradle to Cradle’. They therefore wanted to emphasise that an additional step was required – in view of the steadily increasing global population – in order to optimise the value of material flows and scale back on the need for newly extracted raw materials and waste creation as much as possible.

The Cradle to Cradle (or C2C) principle and the circular economy fall under systems thinking. They encourage us to consider not just the cleaning product in itself, but the entire chain, from the extraction of raw materials, through the manufacturing and use of the product and up to the residual phase, with all the effects on people and the environment resulting from that progression. This way of looking at things is the main difference between the current linear economy and the circular economy towards which we strive.

In the wake of the above-mentioned publication, the Cradle to Cradle label (C2C label) was born. Products have to meet strict requirements, such as the use of biodegradable or recyclable raw materials with a low impact on people and the environment, only this type of product can be eligible to carry the C2C label.

Greenspeed Products from the Organic Cycle:

Cleaning Agents

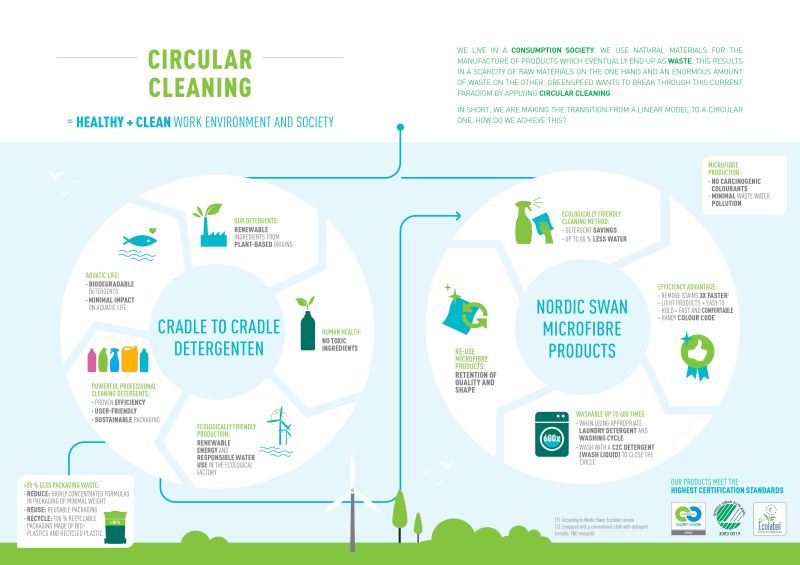

As specialists in sustainable cleaning solutions, Greenspeed continues to work towards circular cleaning. The innovative Probio range has now been awarded Cradle to Cradle Gold certification for probiotic cleaning products

The plant-based range of cleaning agents can replace their petrochemical equivalents without compromising efficacy. In addition to being completely renewable, they break down readily in the watercourse and actually provide a food source for marine fauna and flora.

Products from the Technical Cycle:

Microfibre Cloths

Greenspeed microfibre cloths work best with a spray technique, an ecologically responsible method that reduces water and detergent use.

Thanks to the use of Greenspeed microfibre cloths, dirt is not just removed three times as fast, the method is also comfortable and convenient.

If the right detergent and right wash programme are used, the microfibre cloths can be washed at least 600 times, Using a C2C detergent. Being realistic microfibre cloths with environmental accreditation are more expensive than the standard products, however, many environmentalists claim that sustainable options will ultimately reduce costs, this seems to bear out that thinking.

All microfibre products will ultimately have some effect on the environment but until we develop cloths and mops that pass the Cradle to Cradle test it must be better to choose products which do the least harm therefore best to choose microfibre cloths have Nordic Swan Ecolabel accreditation

Cleaning Trolleys

The Greenspeed C-Shuttle range consists of three types of instrument carts, each made out of 75% recycled plastic; all of the materials used are of the highest quality and completely recyclable.

The carts are very user-friendly; compact and manoeuvrable and provided with a stable handle with bumpers.

N.B. Much of the information in this article is courtesy of Greenspeed International.

Tendering with Greenspeed